CHAR Technologies

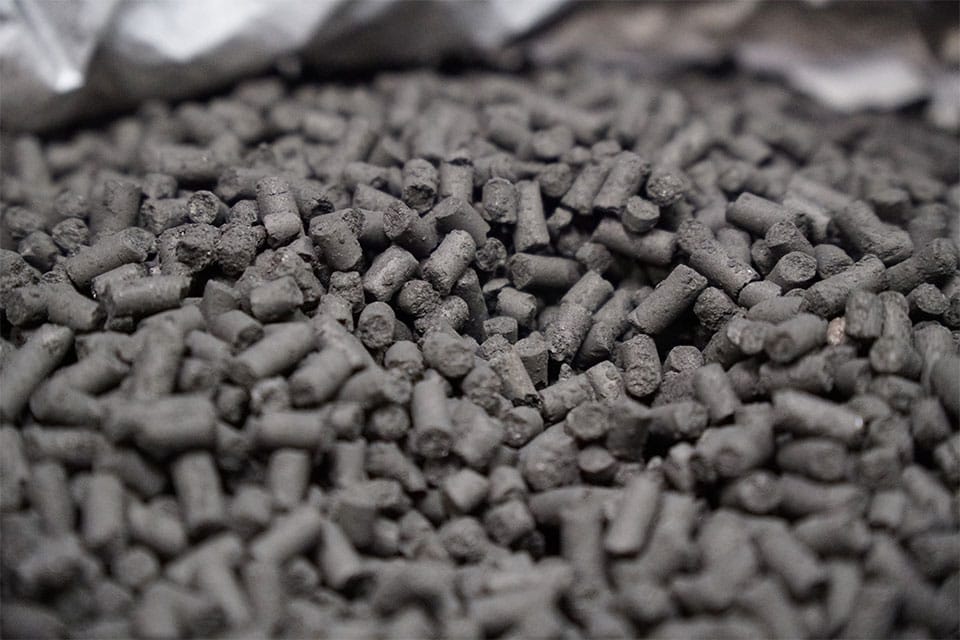

Since its founding in 2011, CHAR Technologies has become a leader in the cleantech field. Using high-temperature pyrolysis (HTP) technology to transform organic waste (predominantly wood waste) into renewable gases and biocarbon, their work is driving decarbonization solutions for a circular economy.

While working on his master’s thesis, co-founder and CEO Andrew White had a moment of inspiration: to use temperatures nearing 800 degrees Celsius for pyrolysis – versus the more common 500-600 degrees – to develop high-quality co-products including activated carbon/biocoal and renewable energy.

In the last decade, the company has had success developing a high-energy and low-greenhouse gas generating biocoal using this technique, with work also being done to perfect the generation of renewable natural gas. Notably, CHAR Tech’s biocoal boasts an impressive 91% reduction in greenhouse gas emissions and is positioned as a breakthrough drop-in replacement for metallurgical coal, making the company a premier partner for heavy industries looking to decarbonize.

Steelmaking is a major carbon-intensive activity and is a crucial area of focus for CHAR Tech. The company is collaborating with leading steelmaker ArcelorMittal and has received funding of C$6.6M from ArcelorMittal’s XCarb® Innovation Fund and signed a MOU where ArcelorMittal Dofasco will purchase 5,000 tonnes of biocarbon produced from CHAR Tech.

“There is tremendous potential for CHAR Tech’s biocoal and RNG to help decarbonize industry. Heavy Industries are becoming increasingly motivated to adopt cleantech and reduce greenhouse gas emissions, which is backed by the support and regulations put forth by the Canadian government to meet their sustainability goals. We’re seeing a turning point across all industries, where converting waste into value, and consuming renewable energy is the new standard,” says Andrew Friedenthal, Director of Business Development for CHAR Technologies.

There is also work being done with First Nations communities and forestry groups to turn wood waste into valuable products. By strategically locating facilities near feedstock sources and energy consumers, CHAR Tech is developing a circular and cost-efficient biomass solution across Canada.

The company is focused on delivering tailor-made solutions that range from designing & developing HTP projects, generating value from valuable outputs, and maintaining/operating facilities.

CHAR Tech has been a longstanding member of the Canadian Biogas Association, Friedenthal says, “The CBA has been a great organization for us to connect with partners who are working toward the same goal of developing renewable energy from organic waste streams. The CBA is an amazing platform that helps advocate for new opportunities and policies to help drive growth for the growth of innovative technologies like CHAR Tech’s HTP, allowing us to expand our pipeline of both suppliers and customers.”

Conferences are also a huge draw for CHAR Tech, “The CBA’s Value of Biogas East and West events are the premier opportunity for Canadian players in the RNG space to share their R&D and project progress, it is a collaborative and learning experience for everyone.”