Hydron

Hydron is innovating biogas upgrading with a low-cost, scalable gas separation technology. Launched in late 2020, Hydron’s founder was intent on leveraging his chemical engineering experience and extensive patents for the purpose of helping hard-to-decarbonize sectors such as transportation meet net-zero requirements. From this vantage point, Hydron is quickly accelerating from start-up status to a company focused on product commercialization by transforming its barren North Vancouver headquarters into a product development and manufacturing facility with R&D labs.

Hydron has a highly skilled technical team focusing on the core technology with an extensive background in adsorption processes and materials and gas separation. Soheil Khiavi, the company’s Founder and President, is a third-time entrepreneur who has worked in the high-tech energy field for more than two decades developing and commercializing gas separation processes and systems. Hydron’s gas-separation products are the cumulation of Soheil’s learnings, expertise, and team building quality.

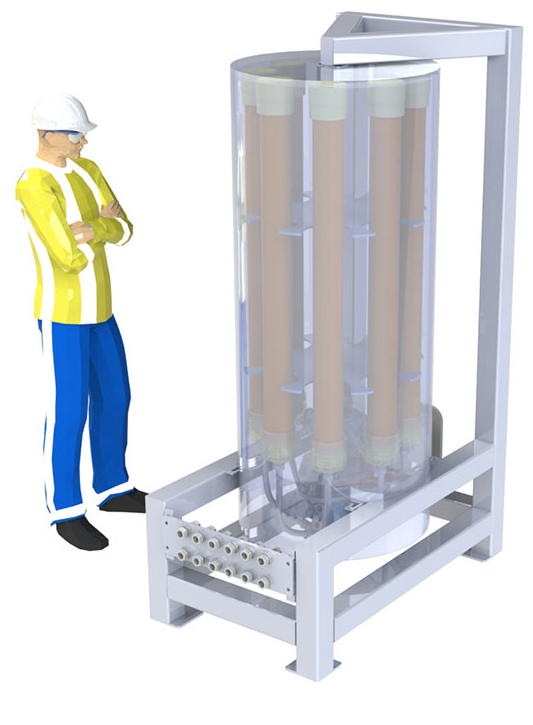

Hydron is commercializing its proprietary multi-swing gas-separation platform technology based on proven products developed by the founder over the past few decades. The company’s proprietary process, INTRUPT, which is short for Intensified Regenerative Upgrading Platform Technology, has applications in biogas upgrading as well as hydrogen purification.

The INTRUPTor, Hydron’s system tailored for biogas upgrading, offers 50% capital and operating cost savings over conventional technologies. The proprietary adsorption-based technology operates under ambient conditions and is suitable for most operations with two orders or magnitude scalability from 20-2,000 Nm3/hr. The high separation efficiency retains over 99% of the product gas and provides minimal methane loss to the environment.

The ability of the INTRUPTor to upgrade gas at atmospheric pressures provides a significant advantage over other upgrading technologies. It reduces cost by cutting the energy required to operate the process and removes the requirement for high-demand components such as feed compressors and exhaust vacuums pumps. It also requires less maintenance since the low pressure minimizes the physical wear and tear on the hardware and active materials.

In March 2022, Hydron received support through the BC Fast Pilot Program to design, build, and operate a pilot-scale, mobile INTRUPTor system that will upgrade biogas produced by anaerobic digestion to RNG. The project, known as the I-Multi Waste-to-Energy Pilot Project, will demonstrate the feasibility of the process during 1,000 planned hours of field testing in 2022. At the end of the field testing, the I-Multi system will continue as a mobile unit that travels between sites in Canada and the US, demonstrating performance under different biogas conditions during the next few years.

Hydron has established meaningful partnerships since inception, and continues to explore partnership opportunities to develop, own, and operate gas separation projects. Hydron is also pursuing field locations in Canada and the U.S. to demonstrate its INTRUPTor systems.

Hydron joined the Canadian Biogas Association (CBA) as members in September 2021. They chose to connect with the CBA early in their establishment because of the resources the association offers, and connections related to being a member. Being new to the industry, engaging with the CBA was critical to helping the company get a solid start on a level playing field.